New stuff

New Stuff!

Yesterday (the 27th), I ordered a whole bunch of stuff for work on the different projects I have.

Translucent Silicone

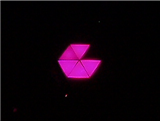

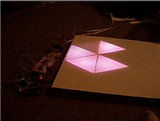

One of the big steps/innovations was the discovery of a little something called Translucent Silicone. This stuff is pimp, and diffuses light like nobody's business. I ordered an engineering sample from Rubber-Cal and got a smallish (2.5" diameter?) circular 1/8" thick piece. The piece itself was probably too thick for what I need, so I ordered 1/16" stuff.

The smallest piece I could order from them was 36" wide x 5' long (lengths go from 5' on up). At ~$100 for 15 sq. feet, it's not cheap, but it's great stuff. It's also flexible and slightly spongy, so it opens up many more uses than the acrylic + contact paper I have been using.

Liquid Translucent Silicone

I also ordered up a sample size of some SORTA-Clear from Reynolds Advanced Materials, which is a liquid translucent silicone, which can be painted or molded/cast into whatever shape needed. This option opens up far more possibilities than even the sheet silicone, as I can make enclosures/balls and edging to satisfy any needs. Simply by carving and dremeling/sanding some pieces of wood, I can get some very simple molds to cast any parts I would need.

LEDs

On a less-exciting, but still cool note, I finally tried out the 3-color LEDs I had gotten a long time ago from Super Bright LEDs. Their output intensity leaves something to be desired (1200, 3700, & 700 mcd for RGB, respectively), the color mixing works wonderfully. I may try using two LEDs per pixel on the cubes, and multiple ones on the sign backdrop, depending on what works.

Two should spread out the light fill much better, especially if I need to go with some pretty thick silicone to diffuse it properly.

Miscellaneous Crap

And finally, to go along with all of this, I also bought:

- 1/4" velcro, finally

- from Augmentative Resources Inc.

- black, 25 feet, mainly cuz I've been stalling so long already

- Scale

- from McMaster-Carr, a great industrial supply site

- used for measuring for the liquid silicone, as it comes in parts A & B that need to be mixed for it to react

- Weld-On #3 acrylic cement

- also from McMaster-Carr

- for joining the sides of the acrylic cubes, of course

- 16oz. mixing cups

- from Reynolds Advanced Materials also

- disposable, for the liquid silicone, and anything else that needs them

- More testing LEDs

- 3500 mcd R

- 8000 mcd G

- 2500 mcd B

- All for testing; I got these to align with the same candella ratios as the 3-color LEDs. If these don't work worth a damn, then I'll just go back and order a bunch more 3-color LEDs and resistors to match the currents.

I should get most of this by mid-late next week (Thursday?), but since Tuesday is a holiday and some places will be short-staffed on Monday, probably not until the following week.

Labels: Side Projects, Supplies